Floor Gapping

ACCEPTABLE GAPPING AND USE OF FILLERS IN SOLID TIMBER FLOORS

With solid timber floors the topic of gapping at board edges and the possibility of filling those gaps is a subject often raised. There are many views on both the acceptability of gapping at floor board edges and also if gaps do exist, whether they can be successfully filled. This information sheet will discuss both these aspects.

WHY DO SOME FLOORS SHOW GAPS?

It is apparent that some solid timber floors stay relatively tight with no observable gapping throughout their life whereas in other instances gaps may be present only during drier months or in some floors gaps may be present throughout the year. There are many factors that affect whether a floor will gap at board edges and these include the flooring moisture content range when installed, the locality environment, internal conditions at the time of installation and after occupancy, board width and the method of installation.

Before considering these, it is important to understand that timber is hygroscopic and that coatings are permeable. Essentially this means that irrespective of the coating applied, flooring boards absorb moisture if air humidity is high and release moisture to the air if humidity is low.

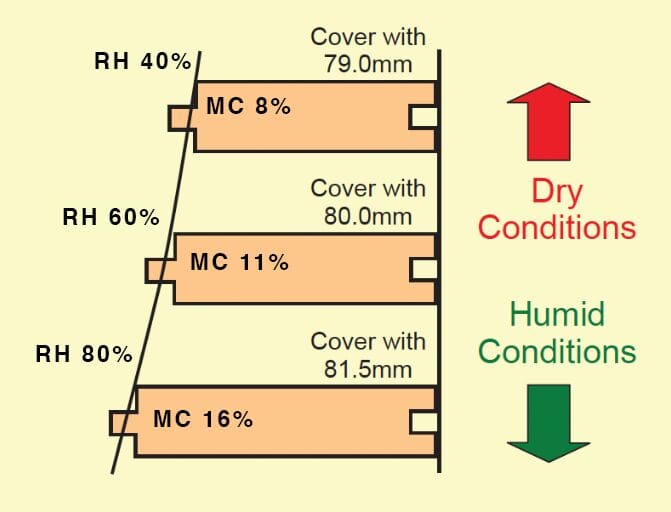

When timber flooring changes moisture content there is a corresponding change in board width. For many hardwood species an unrestrained 80 mm wide floor board will shrink or swell by about 0.25mm for each 1% change in moisture content. The relationship between moisture content, relative humidity and board width is indicatively shown in the diagram.

GAP MINIMISATION IN HOT DRY WEATHER

The laying of a timber floor and when it is subsequently sanded and polished is often dictated by the building schedule and due to this the effects of seasonally hot and dry weather conditions are at times not duly considered. This situation is further exacerbated if during these times the house is unoccupied and locked up for an extended period. This information sheet explains what happens under these conditions and how problems may be alleviated.

WHY SHRINKAGE GAPS OCCUR

The diagram shows the relationship between the air relative humidity, board moisture content and board width. As conditions become drier due to lower air relative humidity, moisture is released from the boards, board moisture contents reduce and the boards shrink. This is a natural process. The consequences of this are that gaps will appear at board edges and greater shrinkage may occur at the exposed upper surface resulting in boards cupping. Temperature has two effects. Firstly, high temperatures within a house will lower the relative humidity making the air drier and secondly high floor temperatures make it easier for the moisture in timber flooring to be released to the air.

VERY DRY CONDITIONS

Many states experience very dry conditions and this is often around Christmas and it is at these times that houses under construction can be locked up for a period of three to four weeks while the builder takes an earned break. If a timber floor has been laid prior to this and weather conditions become very dry then a high degree of shrinkage, cupping and at times checking (surface splits) can result. Weather data shows these conditions as indicated in the adjacent 9am relative humidity graphs below for Perth during the Christmas period (red line).

In Perth during this December and January period the average 9am external relative humidity was 40%. This equates to timber moisture contents of about 7.5% and in a closed up dwelling with higher internal temperatures the conditions can equate to timber moisture contents as low as 4%. This has a drastic effect on timber flooring in an unoccupied dwelling and even if the floor has been coated the effect is still be severe.

The differences between dwellings that have been occupied and those that are not occupied also needs some explanation. Firstly, when a dwelling is lived in there are many sources that add moisture to the air including pots boiling on the stove, pot plants, bathroom showers or evaporative coolers.