Water damaged floors

Timber floors, being solid T&G, engineered, laminate or bamboo, may all experience water damage at some stage in their life.

Home > Information Sheets > Page 4

Exclusive to ATFA’s members are the ever-popular extensive collection of information sheets, where we delve deep into the intricate world of timber flooring. From technical aspects of floors and decks, sanding, coating, to general tips, consumer awareness, OH&S, environmental concerns, and contractor awareness.

Equip yourself with the knowledge to make informed decisions, ensure best practices, and stay updated with the latest in the industry from over 100 technical documents – created by the ATFA for ATFA Members.

Timber floors, being solid T&G, engineered, laminate or bamboo, may all experience water damage at some stage in their life.

Most people who work within the timber flooring industry know that many complaints are caused by moisture problems.

There are many timber flooring products in the market ranging from traditional solid timber flooring through to engineered, bamboo and laminate flooring.

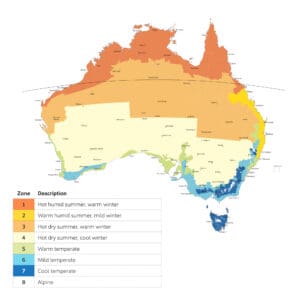

Timber floors in wet areas such as bathrooms and laundries must be protected from moisture in accordance with the Building Code of Australia.

Termites or ‘white ants’ are present throughout Australia and from time to time when building protection is compromised timber floors can be attacked.

Each year as we pass through spring into summer the insect world comes alive and from time to time we see evidence of this in our timber floors.

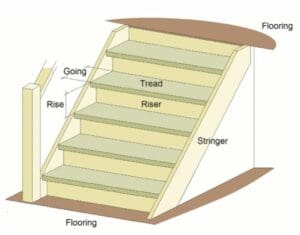

In 2014 the Australian Building Codes Board and the aligning State Government Regulators introduced changed regulations for slip resistance on stairs and ramps within the Building Code of Australia (BCA), part of the National Construction Code (NCC).

When timber floors are sanded and coated it is generally either an existing dwelling or new dwelling that is nearing completion.

Often internal stairs are made from timber or they are clad with timber flooring products. In other situations, timber flooring will be laid after the existing stairs are in place and existing floor covering have been removed.

Solid timber strip floors may be laid directly to joists or over sheet subfloors of particleboard and plywood

In years gone by air-conditioning was afforded by only relatively few, however nowadays air-conditioning is common especially with new dwellings having air-conditioning to part or all the dwelling.

It has become common practice to use adhesives in conjunction with fasteners to fix timber and bamboo flooring to the subfloor.

For as long as there have been timber floors there have been squeaks and it is generally accepted that many floors will make some noise when walked on.

When we refer to slip resistance with timber flooring products we are generally referring to the slip resistance of the coating on the product.

A high percentage of timber floors are laid over concrete slabs. Often a moisture vapour retarding barrier is applied to the slab or a black plastic membrane may be used.

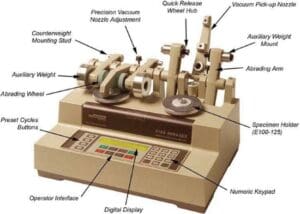

Taber testing is quoted by many coatings manufacturers as a means of conveying predicted wear resistance by a standardised method.

This information sheet provides guidance and test results to the fire hazard properties of common solid timber flooring used in commercial Class 2 to 9 buildings under the National Construction Code.

There have been instances of floor failure due to tenting following the installation of overlay timber floors when direct adhesive fixed to concrete slabs during hot and very dry conditions.

There have been instances of floor failure due to tenting following the installation of overlay timber floors when direct adhesive fixed to concrete slabs during hot and very dry conditions.

Timber floors are often installed in high-rise and unit developments, where it is necessary to reduce noise transmission to acceptable levels through to the dwelling below.