Fire properties of commercial timber floors

This information sheet provides guidance and test results to the fire hazard properties of common solid timber flooring used in commercial Class 2 to 9 buildings under the National Construction Code.

Home > Information Sheets > Page 5

Exclusive to ATFA’s members are the ever-popular extensive collection of information sheets, where we delve deep into the intricate world of timber flooring. From technical aspects of floors and decks, sanding, coating, to general tips, consumer awareness, OH&S, environmental concerns, and contractor awareness.

Equip yourself with the knowledge to make informed decisions, ensure best practices, and stay updated with the latest in the industry from over 100 technical documents – created by the ATFA for ATFA Members.

This information sheet provides guidance and test results to the fire hazard properties of common solid timber flooring used in commercial Class 2 to 9 buildings under the National Construction Code.

There have been instances of floor failure due to tenting following the installation of overlay timber floors when direct adhesive fixed to concrete slabs during hot and very dry conditions.

There have been instances of floor failure due to tenting following the installation of overlay timber floors when direct adhesive fixed to concrete slabs during hot and very dry conditions.

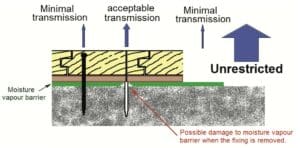

Timber floors are often installed in high-rise and unit developments, where it is necessary to reduce noise transmission to acceptable levels through to the dwelling below.

When installing a solid T&G timber floor directly over a concrete slab, moisture vapour barriers may be applied

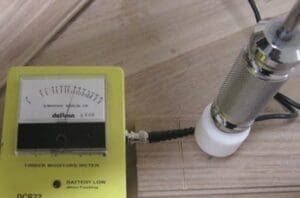

The correct use of resistance moisture meters with timber floors and how to interpret the results is of prime importance.

Some coatings will darken or yellow with time while other coatings may result in a floor becoming lighter with time.

Edge bonding can occur more so with some finishes if they penetrate gaps at board edges and act as an adhesive, and thereby bonding groups of boards together.

In this information sheet, we will look at the various aspects that can cause coatings to fry and provide us with a better understanding of how to avoid it, and also, should it occur, how to address it.

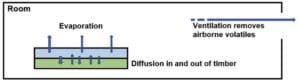

Outgassing, evaporation, diffusion and off-gassing are some of the terms used to describe the movement of volatile species from a coating that has been applied onto a surface.

Coating adhesion failure can be termed delamination, flaking, peeling, bond failure and various other terms.

This information sheet outlines what owners should expect and factors to consider throughout the sanding and coating process for an onsite sanded and finished timber floor.

The practice of changing the colour or appearance of a timber floor via staining or colouring is not a new idea.

The renovation or recoating of prefinished flooring is becoming a more popular request among flooring contractors, particularly for floors in retail environments

Solid T&G timber floors are often re-sanded and coated, and this is part of the benefit of solid timber floors.

When working with cork, each job should be taken on its merits with differences from one site to another likely.

There are a number of aspects that need to be taken into consideration when existing timber floors are re-sanded and coated that the contractor should know and make the owner aware of.

When timber floors and sanded and coated many terms are often used that are at times difficult for those not specifically involved in floor sanding to understand.

When timber floors and sanded and coated many terms are often used that are at times difficult for those not specifically involved in floor sanding to understand.

Functional performance is generally related to after occupancy and includes factors such as wear resistance, slip resistance, ease of maintenance, edge bonding concerns, client health impact etc.