Installation over Acoustic Underlays

Timber floors are often installed in high-rise and unit developments, where it is necessary to reduce noise transmission to acceptable levels through to the dwelling below. Due to this, timber and other similar hard flooring products are often laid on an acoustic underlay. The purpose of this information sheet is to outline the requirements and what must be considered when installing a timber floor where the noise transmission must be reduced (or attenuated). It should also be noted that there are many other factors that relate to the actual noise transmitted – including what the floor space is used for, whether soft soled footwear is encouraged, and whether rugs and runners are used in higher foot traffic areas. Each of these can have a profound effect on the actual noise transferred and the amenity of those living beneath the floor.

Noise and its Control

There are two main types of noise to be considered. The first is the higher frequency noise from music, phones ringing, people talking, televisions and the like. This type of noise is controlled by mass of the floor system (which is mainly from the mass or weight of the concrete); and with timber floors over concrete slabs, the mass of the slab generally provides sufficient control for this not to be a problem. The second type relates to the noise associated with the lower frequency vibrations. This includes footfall noise (particularly from stiletto heels) but also from sub-woofers in entertainment systems. This low frequency tends to vibrate the whole structure including the slab and walls, and is more difficult to deal with. To control this type of noise many things become important including the depth of the slab and isolation of the timber floor from the slab, walls, skirtings and any adjoining other hard surfaces such as tiles.

To control the low frequency vibrations, shock absorbing acoustic underlays play an important role in reducing noise transmission to an acceptable level. However, the choice of underlay and system used will also depend on many factors including the type of flooring, slab thickness, ceiling heights and the type of ceiling system beneath.

Sound pressure is measured in decibels (dB) and an increase or decrease is perceived by us as a change in loudness. Most of us would notice a change of 3dB and a reduction of 10dB would sound about half as loud.

The International Standard ISO 717-2 is used to assess the noise transmission through a floor into a receiving room below. When tests are being undertaken the LnTw or ‘Weighted Standardised Impact Sound Pressure Level’ is determined, which provides a single figure on which to assess the noise transmission. The lower the figure the better the attenuation of the noise and the better the result. The standard also takes into consideration and makes adjustment for whether the receiving room is furnished or not.

What does a moisture vapour barrier do?

When we talk about moisture vapour barriers it is important to understand that when we are referring to vapour, it is the invisible moisture that is present in air. We are not talking about liquid water. However, if this moisture vapour (which is measured as relative humidity) is too high beneath a floor then it will cause the flooring to absorb the moisture from this source and may result in cupping and other expansion related problems. It is also important to realise that moisture vapour barriers are not ‘water proofing membranes’ and they will allow a small amount of moisture vapour transmission through them. The timber floor, even with finishes applied, also permits moisture vapour to pass in, out and through them. That is why we have seasonal movement in timber floors. What is important is that the timber flooring can allow this moisture vapour transfer at a much faster rate than that which may occur from the concrete slab.

Compliance requirements

NCC Requirements

The NCC requires the LnTw to be not more than 62dB for floors separating dwellings. This provides industry with a number to work to and with selected systems this is easily achieved. For comparative purposes, it should be noted that carpet will generally achieve an LnTw of about 40, and for bare concrete with a 175mm slab a LnTw may be about 70.

Comparative tests of underlay systems to bare concrete can be used to provide useful results and specific field tests on installed floors are also being undertaken to determine whether NCC requirements are being met. In such tests the size and shape of the room and degree of completion of both the transmission and receiving rooms are recorded. Aspects of slab thickness and ceiling material beneath the floor are also recorded. The floor or flooring sample is then tested with a tapping machine to create the noise; and with a set procedure in the receiving room, a noise level meter is used to record the results. From the results over a range of frequencies and considering such aspects as background noise, the LnTw is determined.

Tests undertaken with timber flooring adhesive-fixed to acoustic underlays, which in turn are adhesive-fixed to the slab, often achieve LnTw results of between 50 and 60 when the bare 175mm thick slab is about 70. Systems may struggle to comply with thinner slabs where greater attention is necessary.

Engineered floor laid on acoustic underlay

Strata Management Requirements

Although the above provides the necessary guidelines for construction to meet NCC requirements, we must also consider the Strata Schemes Management Act.

This act permits an apartment block to have its own set of by-laws which owners must comply to and as such these can add additional restrictions and in some instances the requirements are much less well defined than the NCC requirements. For example, a by-law may indicate that an owner must ensure that their floor space is covered in such a way as to prevent noise transmission that is likely to disturb the peaceful enjoyment of the owner beneath. The by-laws could also call on an acoustic report from an Acoustic Consultant.

This highlights the need to obtain the specific by-laws for an apartment block in the early stages of any flooring project.

Council Requirements

In addition to the above some councils are requiring separating floors in apartment blocks to have LnTw of 40 to 50. This is still quite achievable with timber floor systems however greater consideration is needed of the overall system including the ceiling beneath and acoustic underlays specifically designed to provide greater attenuation. As to be expected higher levels of attenuation are subject to higher system costs.

Association of Australian Acoustical Consultants

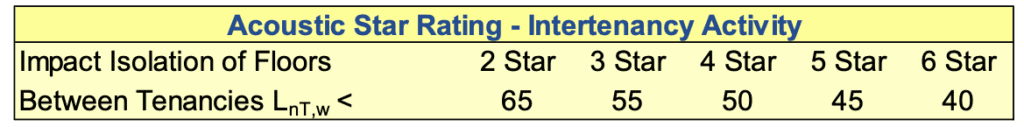

One association active in building acoustics is the Association of Australian Acoustical Consultants (AAAC) and they have guidelines for rating apartment and townhouse acoustics available from their website (www.aaac.org.au). A star rating system has been developed by its members and is seen as being complementary to the compliance requirements, as outlined above, that are already in place. Only AAAC members can provide this star rating for a building and it should not be confused with the other star ratings for energy etc. that are used.

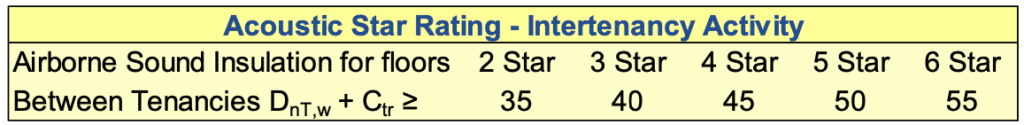

Acoustical Star Ratings

The purpose of the star rating is to better fulfil owner expectations regarding the acoustic performance of the building and noting that some owners do not consider that building to meet NCC requirements is adequate, particularly in the more expensive apartments. The star rating system can therefore be used to assist design and provide consistency in the rating of one apartment block to another. It should be noted that with the star rating system, the floor is only one contributor to the rating as it covers other aspects such as intrusion of external noise, noise through walls and noise from lifts etc. Therefore, although some product underlay information may show both LnTw and a star rating it must also be recognised how the two also differ. Bearing in mind that the star rating covers noise from a number of sources, the following relates to the impact isolation of floors between tenancies. It is evident from this table that floors meeting NCC requirements are awarded the lowest number of stars and that to achieve a 6-star rating would require specific design.

Note that with LnTw a low number is ‘better’ and with DnTw+Ctr a higher number is ‘better’. Note also that with a 2-star rating sounds in the ‘receiving’ room would be clearly audible and with a 6-star rating not audible.

The choice of system and products

In the market there are many product and many systems that range from thin foam underlays, applied products that provide acoustic benefits, and various shapes and thicknesses of often rubber-based underlays. Some are applicable to floating floor installations while others are for stick down applications.

In many new developments, floors are more commonly being tested by Acoustic Engineers. However, tests are expensive, often running into a few thousand dollars per test. Such an approach may be prohibitive for owners of existing apartment blocks. The next best approach is to consider tests of systems that are similar to what you are considering. Many acoustic insulation material suppliers will have undertaken tests on something similar and as such similar results would be expected.

However, it must be stressed that there is still a degree of risk in this as no two situations are exactly the same. Note also that for full compliance to the NCC an exact replica would be required. It must also be stressed that it is necessary to compare apples with apples and realise among other things that slab thickness is very important. For example, if the slab thickness is 150mm, then test results on a 175mm thick slab cannot be used as even a rough a guide, even though the acoustic underlay and flooring may be the same.

Similarly, different floor systems using the same acoustic underlay will also give different results.

The CSIRO has undertaken testing on a number of different timber flooring systems for acoustic underlay manufacturers and the results provided in brochures from them often provide a good starting point for comparison between one product and system and another. In these tests the flooring system is generally laid on a plastic sheet over a concrete slab measuring 3.2m x 3.6m.

The tapping machine is placed diagonally on the floor and tests are undertaken consecutively in four locations. The results are then averaged.

With the acoustic performance of floor systems there are some general principles to consider, as follow:

- A thin laminate floating floor will deflect to some degree under the hammers and allows the acoustic underlay to do its job and absorb the sound and vibration generated in the area of the hammers. Thicker floor systems with higher density hardwood do not perform as well, as with less deflection or flexibility of the board the sound waves are distributed over a wider area and the influence is greater. Therefore, the timber flooring product has a significant effect on test results. Ceramic tiles with almost no flexibility provide greater sound transmission than timber floors.

- Acoustic underlays are manufactured from different materials, and are of different profiles and densities, but the thickness from different suppliers is frequently the same. Even though the thickness of the acoustic underlay may be the same, there can be a significant difference in the performance of one product compared to another and therefore you cannot substitute products and expect to get the same results.

- The concrete slab thickness has a significant effect with 175mm thick slabs often having a sound transmission of about 70dB but 150mm thick slabs about 80dB.

- Timber flooring systems including acoustic underlays often provide about 10 to 20dB attenuation (reduction in noise).

- If there is a suspended ceiling in the room beneath the floor, then some further attenuation can be expected.

A test report or information about the acoustic performance of a flooring system will generally contain the following:

- The timber flooring material e.g. 14mm T&G Engineered Timber

- The acoustic material e.g. 5mm acoustic mat, type and manufacturer

- The method of fixing e.g. polyurethane adhesive

- The slab thickness e.g. 150mm

- The noise transmission through the bare slab e.g. 79dB

- The attenuation or reduction in noise transmission e.g. 19dB

- The LnTw e.g. (79-19=) 60dB

In the example above the system complies to NCC requirements.

In summary:

- Be aware that the requirements of both the NCC and the Strata Schemes Management Act need to be considered.

- The only way to prove that specific sound attenuation criteria has been met is by testing in the unit or apartment where the floor is to be laid.

- If relying on comparative tests, then there are risks that the sound attenuation (reduction) will differ to some degree (better or worse) in the actual dwelling where the floor is being laid. This is also when systems – the flooring, the acoustic underlay, the slab and ceiling beneath – appear the same. It is also only appropriate to make comparisons with systems that match your own.

- Comparisons, particularly with CSIRO tested systems (often available from acoustic underlay manufacturers) are useful and may be all that is necessary, particularly if the tested floor system that is similar is significantly below the NCC required value. When evaluating data be sure to compare apples with apples.

Other considerations

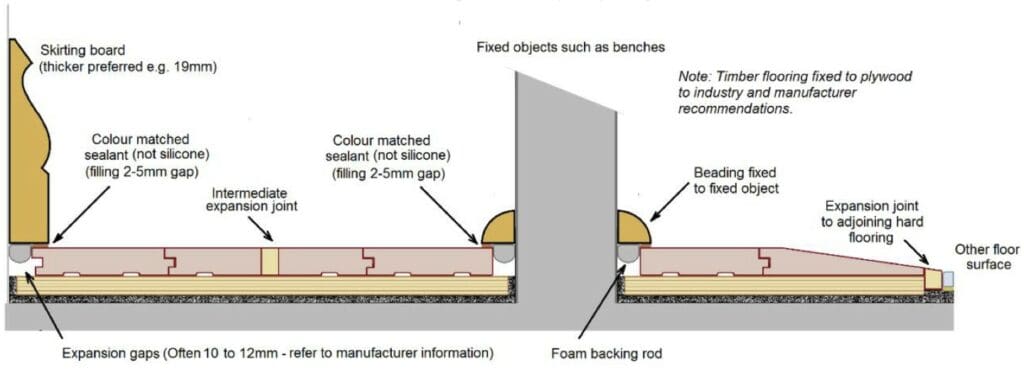

It is important that the flooring system chosen is proven in practice with regard to the fixing of the flooring and the acoustic underlay (as applicable), particularly with solid timber flooring which can exert high forces after installation. With solid timber floors it often requires an intermediate layer of plywood between the flooring and the acoustic underlay. With the system that is to be used, both the flooring manufacturer and the acoustic underlay supplier need to be fully accepting of the installation method used and be satisfied that the installation will perform under the expected internal environment conditions that the floor will experience. This includes the floor’s performance with heating and cooling systems operating and possible naturally higher humidity conditions in coastal environments or during construction. As such, specific written installation instructions should be provided and adhered to. When fixing directly to the acoustic underlay material, flooring manufacturer warranties and performance warranties need to be considered as this often falls outside of published floor installation practices.

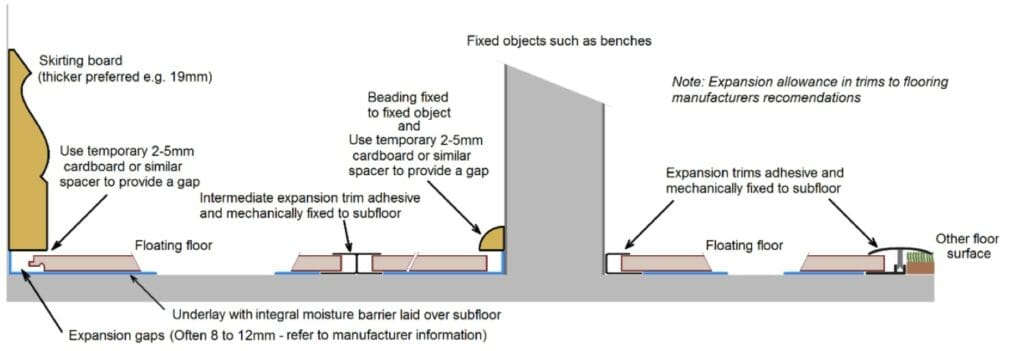

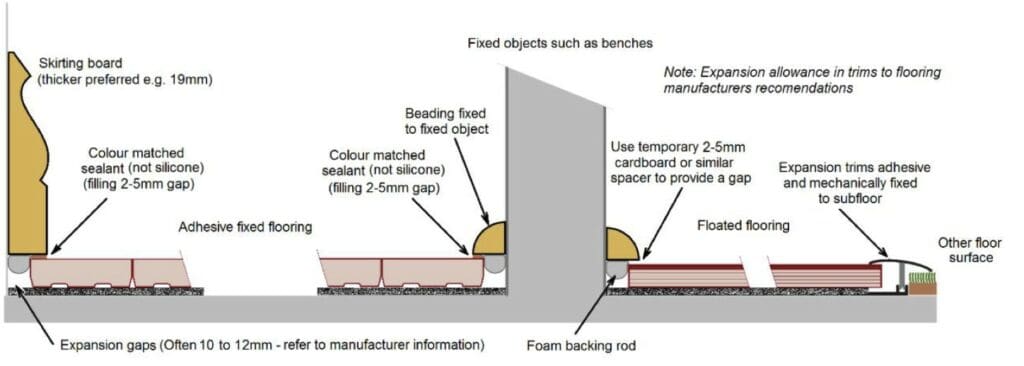

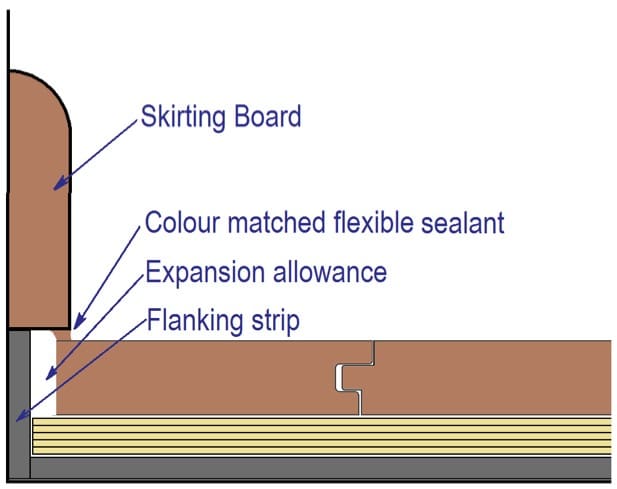

In addition to paying attention to the fixing of the floor it is also necessary to pay attention to the perimeter of the floor. This is because noise can travel across the floor and if hard up against walls it can travel through the walls and into the adjacent units. This is referred to as flanking noise. Manufacturers of acoustic underlay often have details for what needs to happen at the edge of the timber floor – that is, no direct connection to the skirtings and often flexible sound insulation beneath the skirting.

A typical detail is shown in the above diagram and similar details apply where the timber floor may for example abut a tiled area. Note that all floors require expansion allowance to walls and in these installations, it is not unusual for the skirting to be 2-5mm or so higher than the floor and for the gap to be filler with a flexible sealant. In other areas such as at door jams, a similar allowance is necessary to ensure no direct contact with the flooring.

Finally, all concrete subfloors require evaluation and preparation prior to the installation of the floor. This includes the slab surface being sound, the slab being flat, dry and free from contaminants that can affect adhesion. Moisture vapour barriers may also be necessary. Unless floated, the systems invariably rely on direct bonding of the acoustic underlay to the slab and the flooring or an intermediate layer to the acoustic underlay. For this reason, greater care and attention is necessary in the preparation to ensure that the required bond strength is achieved and to minimise possible drummy spots.

Specific installation practices

Considering the internal environment

It must be considered that these installations are not on ground floor slabs or with natural ground in the subfloor space beneath, where greater care is needed with regard to slab conditions and possible moister conditions under the floor, and where internal humidity can be higher. Whether the building is two-storey or multi-storied the conditions within upper level apartments are generally more stable and due to this there are relatively few expansion concerns with timber floors. Any problems that do arise are generally from building leaks and similar ingress. As such, apartments generally provide good environments for timber floors and installation practices reflect this.

Checking the subfloor

With the installation of all timber floors it is necessary to check that the subfloor is suitable for the flooring system to be installed. Such requirements are set out in ATFA publications for solid timber flooring, engineered flooring and bamboo flooring. Flooring manufacturers also often provide advice for their particular products. Important aspects to be considered are:

- Assessing the moisture in the subfloor – this is necessary as relatively new concrete can still hold significant volumes of water and such testing is needed to determine if further protection is required. Sheet subfloors (plywood and particleboard), if becoming wet during construction, often dry quickly and testing of solid timber bottom plates – just above the sheet floor level –can provide a good indication of sheet subfloor moisture content. Note that moisture meters are not accurate in sheet subfloors.

- Ensuring the slab has integrity – When adhesive-fixed systems are used, this is a simple test by trying to gouge the surface of the slab to ensure that the surface layers of concrete are strong. The concrete should not be able to be scored by the testing object as this would indicate weak surface layers. Any weak layers need to be removed.

- Ensuring the slab is clean – All adhesive manufacturers require a clean surface for adhesives. Take special care if compounds have been applied to the slab to assist curing. If these are not removed, most adhesives will not cure. Droplets of water should soak quickly into a slab and if the water droplets bead on the surface, adhesion problems occur. In such cases the concrete surface needs to be ground to remove the compound.

- Ensuring the slab is sufficiently flat – Requirements differ depending on whether products are adhesive-fixed or floating and different flooring product manufacturers have different requirements. However, as a guide, for adhesive and mechanically fixed floors a flatness where there is no more than a 3mm gap below a 1.5m straight edge resting on the slab is applicable. Where there is adhesive but no mechanical fixing, a flatness where there is no more than a 3mm gap below a 3.0m straight edge. For floating floors other than laminate no more than 3mm below a 1.0m straight edge and for laminate no more than 2mm below a 1.0m straight edge. Note the difference between flatness and level. Flatness relates to the undulation in the subfloor whereas ‘level’ relates to the likes of one side of a room being lower that the other. Subfloors do not need to be level to successfully lay a timber floor and will not usually be checked or corrected by the floor installer.

Choice of acoustic underlay

As indicated earlier in the information sheet there are specific underlays for specific flooring products, and which also achieve the necessary attenuation. It was also pointed out that two products of the same thickness from different manufacturers are also likely to have different properties. The underlay is only part of the overall system and therefore it is necessary to seek advice from reputable companies able to provide the advice and technical support necessary for a successful installation. Guessing and using an inadequately tested underlay has resulted in costly remedial work.

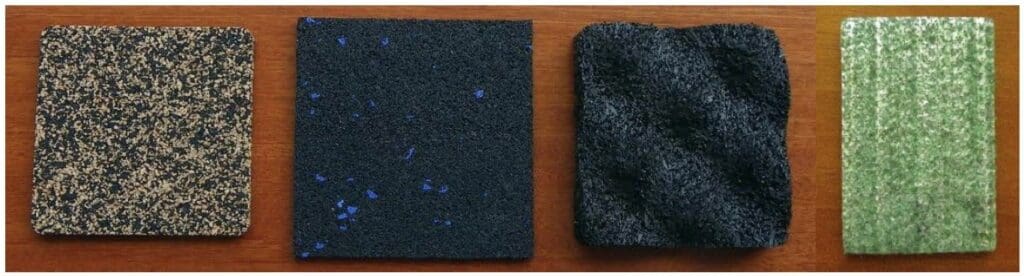

With the four underlays shown, the first is 5mm thick cork and rubber compound specifically designed for the likes of parquetry floors which need block edges firmly supported. The second is a 3mm thick rubber-based product used where moderate attenuation is required, and third is a 17mm thick rubber-based product, which has dimples on the underside as shown, and is used where greater attenuation is required. The fourth product is acoustic membrane also specifically designed to limit sound transmission.

In addition to those examples above there are also some ‘slotted mat’ systems, where often a higher strength adhesive is applied in the slots and the timber flooring laid on top. The flooring is therefore intermittently adhered to the slab through the slots.

Acoustic underlays come in different densities and materials to cater for all flooring types; however, it is also important to understand that higher or lower density does not necessarily relate to performance characteristics. For example, composite products of cork and rubber will have a lower density than straight rubber-based products, but particle size and composition are also important. Ultimately, what is necessary is to achieve the required attenuation or noise reduction; and the acoustic underlay, although an important part of the solution, it is one of several aspects that will affect the design. Again, the importance of gaining appropriate advice from consultants and companies experienced in floor acoustics is advised.

It also needs to be considered that the focus is often on impact noise transmission, yet airborne noise inside the dwelling, which is generally not tested by flooring manufacturers, is also an important amenity aspect for the owners. With floating floors, underlay selection can have a profound effect on the ‘reflected’ noise heard when walking across the floor. Some underlays are very good at achieving both a quiet floor to walk on and solid feel underfoot, while with others the floor will be very hollow sounding. A simple ‘tap’ test in the dwelling that the flooring is being installed in – using different underlay samples – can easily demonstrate this. Such aspects should be considered when selecting an underlay.

Installation methods

It is important to understand that the sound insulation system provided or developed by the acoustic consultants must be followed; but it is also important for the floor installer to abide by standard installation practices for the flooring product being used.

Many of the companies providing acoustic underlays also provide some advice on installation. There are several systems used which include thin foam underlays with sound attenuation properties that are laid over the subfloor for the likes of floated laminate or engineered flooring. With other systems using recycled rubber products the acoustic underlay can for some applications be loose laid or often adhesive-fixed to the subfloor, and flooring either floated or adhesive-fixed to the underlay as applicable. With other products, recommendations are to adhesive fix the underlay to the subfloor, and flooring either floated or adhesive-fixed to the underlay, as applicable. For solid strip timber flooring, plywood is usually adhesive-fixed to the underlay and the timber flooring fixed to the plywood.

This therefore indicates a wide range of systems and it is important to use the acoustic system as set down by the manufacturer. Provided below are examples illustrating the main principles important for successful installation of the different systems.

Foam underlay with floating floors:

This method is used with floating engineered, laminate and bamboo floors